Say goodbye to labour intensive excess packaging

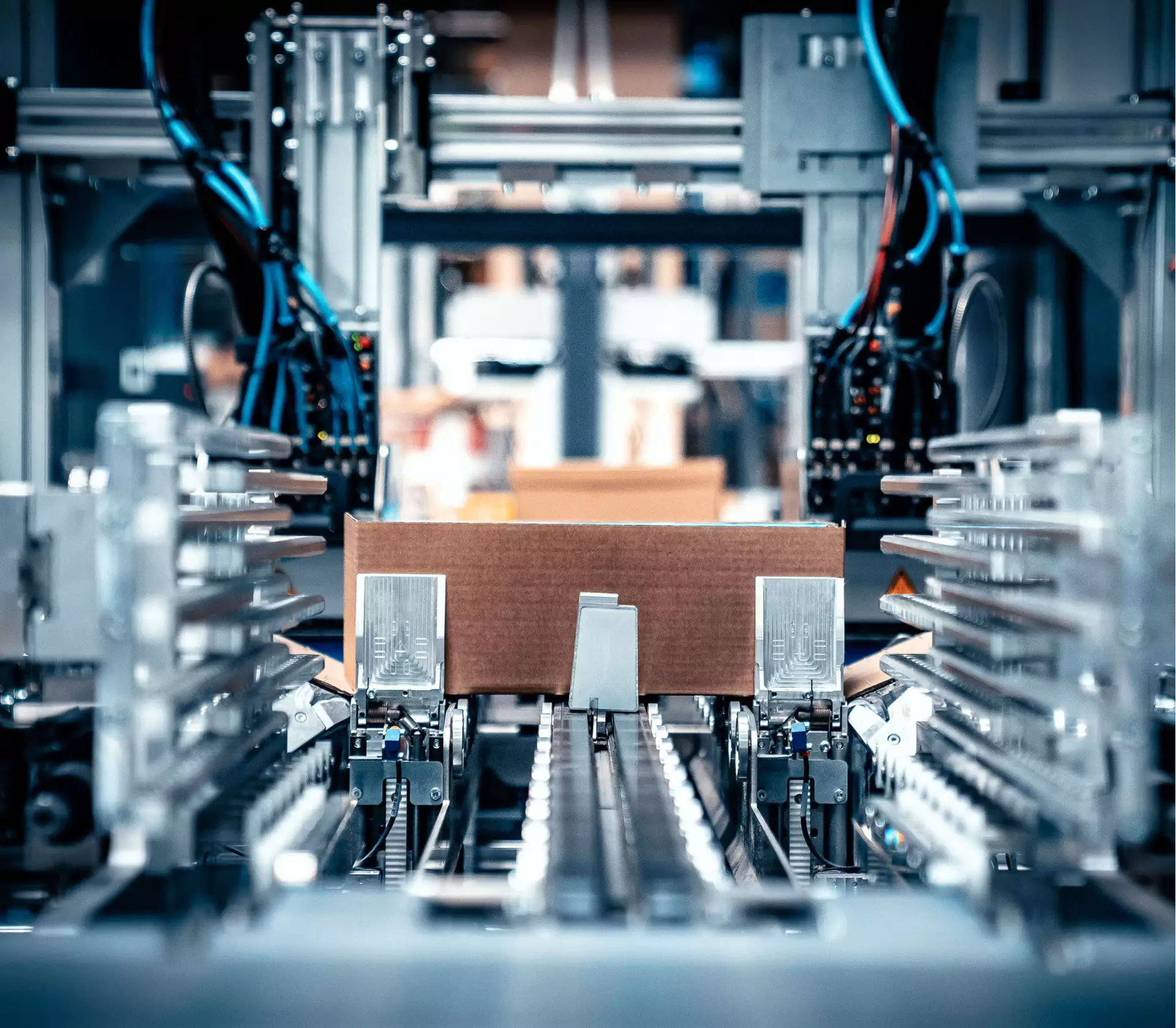

With the capability to tailor-make up to 1,100 packages per hour, for multiple or single item orders, Sparck Technologies’ packaging systems offer automated solutions for warehouse operations challenged by increasing order volumes, labour shortages and growing demands for sustainable packaging solutions.

Using 3D scanning technology, these award winning automated packaging solutions will build, seal, and label a fit-to-size shipping box around each unique order in just a matter of seconds – flexibility that offers over 40 million different box sizes.

The CVP Impack measures, constructs, tapes, weighs, and labels each order creating the right size box for each consignment. Box anything from a pair of headphones to a sleeping bag roll, and all sizes in between.

With its capability to make ultra slim boxes with a minimum height of just 28mm the CVP Everest offers a truly sustainable packaging experience while keeping up with high volume operations.

Share your details for further information from our expert team